Researchers at the University of Maryland have been awarded contracts from the US government to support their work in counterfeit microelectronics detection.

The contract comes from the Defense Microelectronics Activity (DMEA), the organization within the US Department of Defense that is tasked with providing microelectronic components and assemblies for legacy systems.

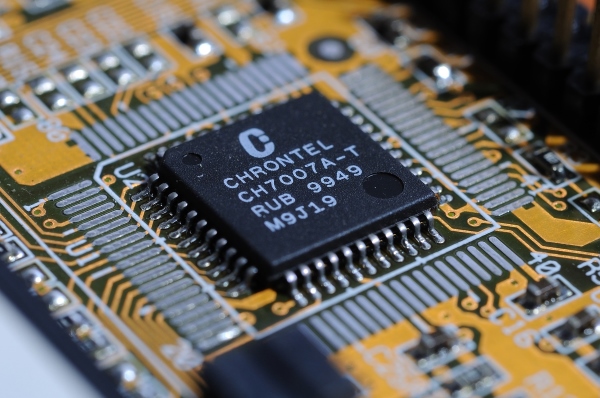

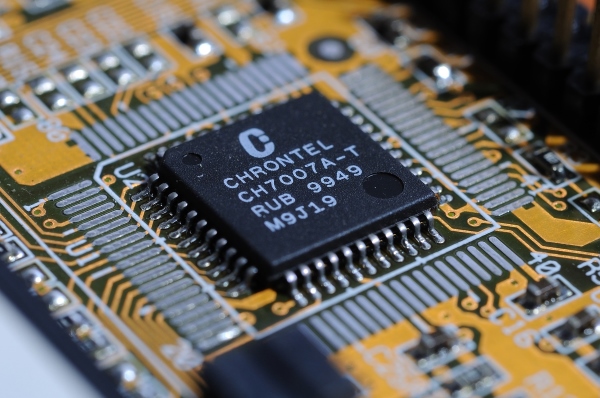

DMEA has been given the task of setting up a pilot programme to test how machine vision-based imaging technologies could be deployed to counterfeit microelectronic detection under the 2019 National Defense Authorization Act (NDAA).

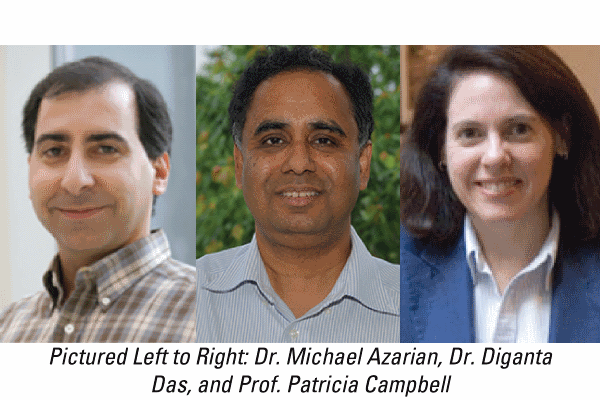

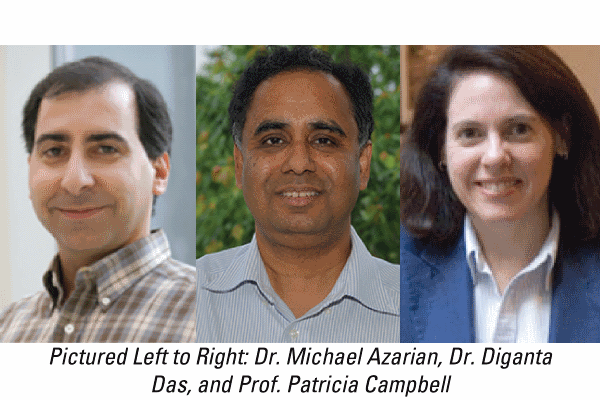

To get that going, it has awarded contracts to Dr Michael Azarian and Dr Diganta Das of Maryland’s Centre for Advanced Life Cycle Engineering (CALCE), who will lead a blind round-robin test effort to evaluate newly developed as well as conventional methods for counterfeit detection.

Helped by component distributor SMT Corp – which is at the sharp end of efforts to detect counterfeit electronics as a primary supplier to the US defense and aerospace sectors – the CALCE team will look at applying machine-vision methods currently used for other purposes to counterfeit detection.

The pilot will also evaluate the technical maturity of new detection methods and recommend ways to improve the integrity of the supply chain for integrated circuits, according to CALCE.

“Machine-vision detection technology includes systems that leverage side-channels (also known as second-order effects) and/or machine learning algorithms to assess the authenticity of a microelectronic device,” it said in a statement.

“CALCE will also determine the technology readiness levels (TRL) of several such tools to help the government and industry select the most effective and practical technologies.

It’s well recognised that components that are at or near obsolescence are at a high risk for counterfeiting, and it has also been documented that counterfeiters in China and other countries use electronic waste, much of it exported from the US, as raw materials to create fake parts that are then sold as new.

Last year, a US-based electronics distributor was sentenced to nearly four years in prison for selling counterfeit integrated circuits obtained from China. According to the Department of Justice, some of these counterfeit microchips ended up in a classified weapons system.

With that in mind, lawmakers have revived legislation proposing to restrict exports of untested, non-working electronics. The Secure E-Waste Export and Recycling Act (SEERA) – which has bipartisan support in the House of Representatives and the Senate – would require domestic recycling of e-waste.

The problem goes back many years of course. In 2010/2011 the US Department of Defense said it had identified upwards of a million counterfeit components in the military supply chain, while a report from market research firm IHS published in 2013 indicated there had been more than 12m reports of counterfeit electronics parts in the prior five years.

In 2016, the DoD published new rules – the Defense Federal Acquisition Regulation Supplement (DFARS) – to strengthen the process for acquiring electronic parts and to help prevent counterfeits ending up in military systems.

Meanwhile, CALCE is also getting involved in appraising whether the legal landscape is fit for purpose in the fight against counterfeit electronics.

It has teamed with the University of Maryland Carey School of Law, in an effort led by Prof Patricia Campbell, to “review current applicable laws, regulations, and policies regarding the mitigation of counterfeit electronics.”

The project will attempt to recommend new laws and regulations that can promote the adoption of effective practices and tools to mitigate the counterfeit threat.

©

SecuringIndustry.com